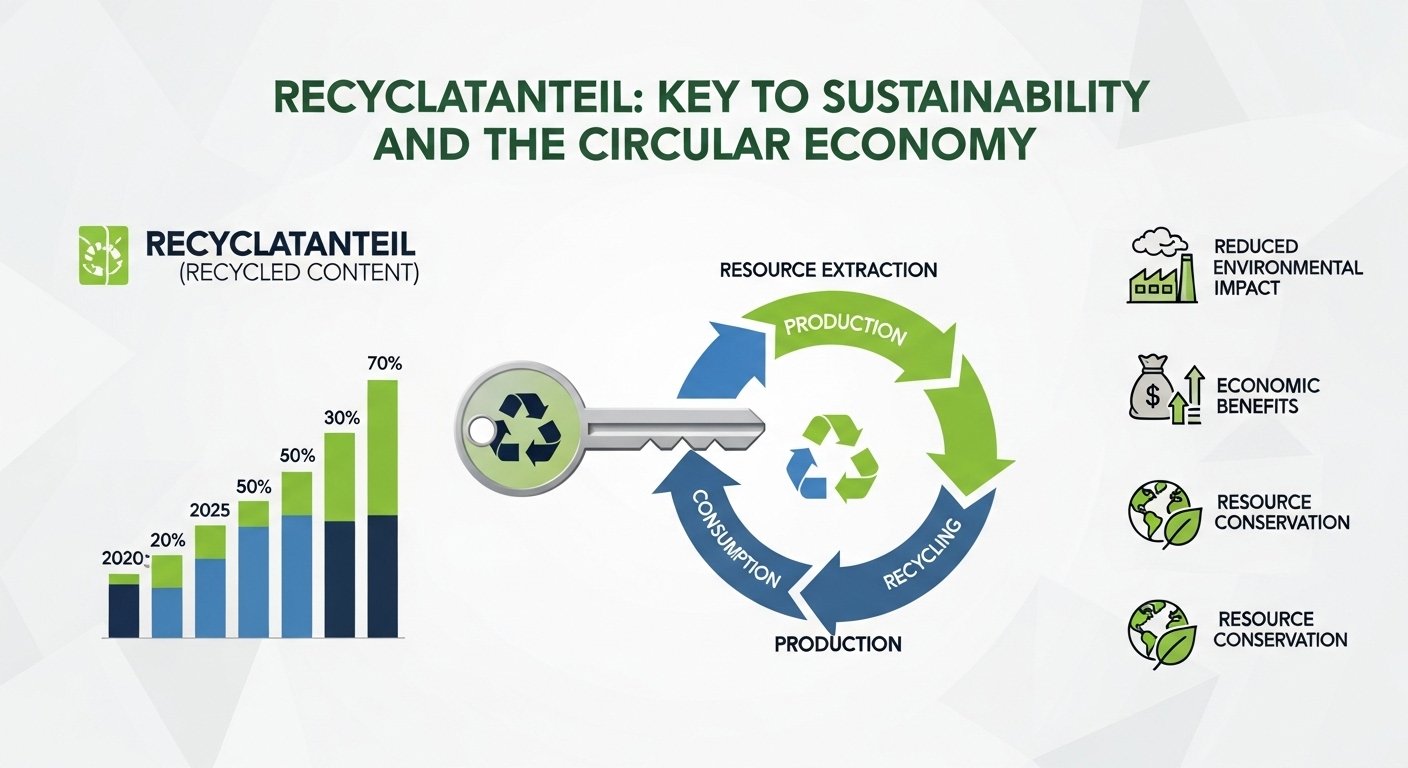

Recycling is more than just a buzzword; it’s a vital piece of the puzzle for creating a sustainable future. As we grapple with pressing environmental challenges, the spotlight shines on how we manage waste and resources. Enter “Recyclatanteil,” an innovative concept that emphasizes incorporating recycled materials into production processes. It isn’t just about reducing landfill waste—it’s about reshaping our economy to function in harmony with nature.

In this journey toward sustainability, every small step counts, and understanding Recyclatanteil can be the key to unlocking significant change. Join us as we explore its crucial role in fostering a circular economy and why businesses should prioritize its implementation for both profitability and planetary health. The path ahead is promising, but it starts with knowledge—and that’s what we’re here to share!

Understanding Recyclatanteil and its Role in the Circular Economy

Recyclatanteil refers to the proportion of recycled materials used in production. Its significance lies in reducing waste and conserving resources.

In the circular economy, recyclatanteil plays a pivotal role. Instead of following a linear model—take, make, dispose—the focus shifts to reusing and recycling existing materials. This approach minimizes environmental impact while promoting sustainability.

Integrating recyclatanteil helps companies close the loop on resource consumption. By utilizing recycled content, businesses can lessen their dependence on virgin materials.

This shift not only benefits the planet but also creates economic opportunities. As demand for sustainable products grows, companies that embrace recyclatanteil position themselves as leaders in innovation and responsibility.

Understanding this concept is crucial for any organization aiming to thrive within an eco-conscious marketplace. The future hinges on how effectively we can incorporate recyclable materials into everyday manufacturing practices.

Benefits of Incorporating Recyclatanteil in Production Processes

Incorporating Recyclatanteil in production processes presents numerous advantages. First, it conserves natural resources. By using recycled materials, companies can reduce their dependence on virgin resources.

Additionally, this practice often leads to cost savings. The expenses associated with raw material extraction and processing can be high. Using recyclatanteil helps mitigate these costs over time.

Moreover, integrating recyclatanteil enhances brand reputation. Consumers today prioritize sustainability and are more likely to support businesses that demonstrate environmental responsibility.

Another significant benefit is compliance with regulations. Many regions impose strict guidelines regarding waste management and carbon footprints. Embracing recyclatanteil ensures alignment with these evolving standards.

Utilizing recycled content fosters innovation within product development. Businesses are encouraged to rethink designs and processes for better efficiency while minimizing waste production altogether.

Case Studies: Companies Successfully Implementing Recyclatanteil

Many companies are now embracing the concept of Recyclatanteil, demonstrating its potential for a greener future. A notable example is Unilever, which has set ambitious targets to incorporate recycled materials into its packaging. They aim for 100% recyclable or reusable plastic by 2025 and have already achieved significant milestones.

Another leader in sustainability is Coca-Cola. The company recently announced that it plans to use at least 50% recycled content in its PET plastic bottles by 2030. This commitment not only reduces waste but also fosters a culture of recycling among consumers.

In the automotive sector, BMW stands out with its focus on circularity. The brand integrates recyclatanteil into producing new vehicles, aiming to reduce resource consumption while maintaining quality standards.

These examples illustrate how integrating recyclatanteil can lead to innovative solutions and inspire other businesses to follow suit.

Challenges and Solutions for Increasing Recyclatanteil Usage

Increasing the recyclatanteil in production processes isn’t without its hurdles. One major challenge is the inconsistent quality of recycled materials. Many manufacturers worry that using recycled inputs could compromise their product standards.

Moreover, there’s often a lack of awareness about the benefits of incorporating recyclatanteil. This can result in hesitancy among businesses to switch from traditional materials to recycled alternatives.

To tackle these issues, education plays a crucial role. Workshops and seminars focused on demonstrating successful case studies can inspire companies to embrace change.

Another solution lies in enhancing recycling technology. By improving sorting and processing methods, we can ensure higher-quality recyclable materials are available for use.

Collaboration between different industries also fosters innovation. Partnerships can lead to shared resources and knowledge exchange, making it easier for all involved to increase their recyclatanteil usage effectively.

The Future of Recyclatanteil and its Impact on Sustainability Goals

The future of Recyclatanteil holds immense potential for advancing sustainability goals. As industries pivot toward eco-friendly practices, the integration of recycled materials is becoming essential.

Innovations in recycling technology are paving the way for higher quality recyclates. This means that more products can be manufactured using a greater proportion of recycled content without compromising on performance.

Consumer awareness is also rising. People increasingly prioritize brands that commit to sustainable practices, pushing businesses to adopt higher Recyclatanteil in their offerings.

Regulatory frameworks are evolving as well. Governments worldwide are setting ambitious targets for waste reduction and recycling rates, incentivizing companies to focus on incorporating Recyclatanteil into their production lines.

Collaboration between sectors will amplify these efforts. Partnerships among manufacturers, recyclers, and policymakers can create robust systems that ensure effective use of recycled materials while promoting circular economy principles across industries.

Conclusion:

The importance of Recyclatanteil cannot be overstated. As we navigate the complexities of sustainability, its role in the circular economy becomes increasingly vital. Companies are discovering that integrating recyclatanteil into their production processes not only helps reduce waste but also enhances their brand value and consumer trust.

Successful case studies illustrate how businesses can thrive by embracing recyclatanteil. However, challenges remain in scaling up these practices across industries. A collaborative approach involving innovation, technology, and government support is essential to overcome these hurdles.

Looking ahead, the future of recyclatanteil appears promising as more organizations recognize its impact on achieving sustainability goals. The shift towards a circular economy will depend heavily on our commitment to increasing recycling content in products and materials.

The path forward is clear: investing in recyclatanteil is investing in a sustainable future for all.